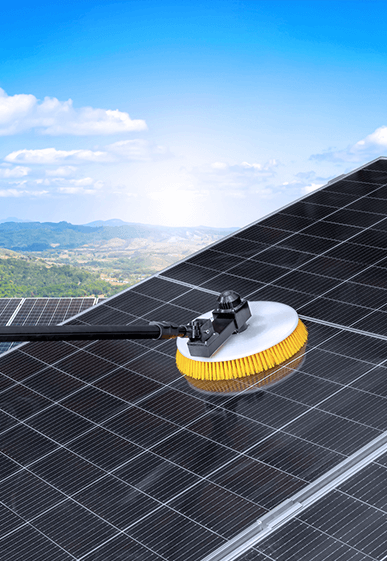

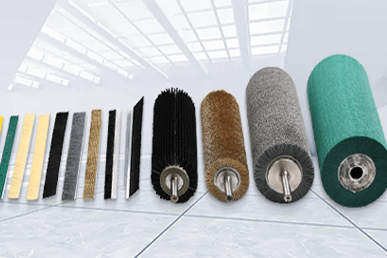

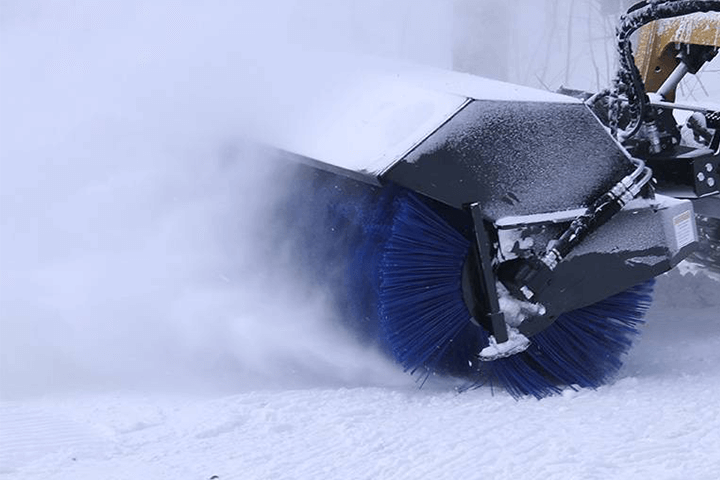

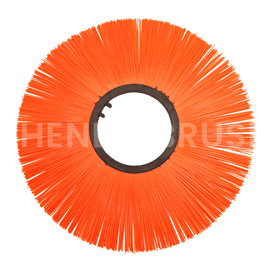

Wafers for Skid Steer Sweeper Attachment/Power Angle Broom Part

Wafers for Skid Steer Sweeper Attachment/Power Angle Broom Part

| Brand | Zhenda |

| Type | Sweeper Wafer Broom/Ring Brush |

| Application | Skid Steer Angle Broom Replacement Bristle |

| Manufacturer | Anhui Zhenda Brush Industry Co., Ltd. |

| Place of Origin | Yuantan, Anhui |

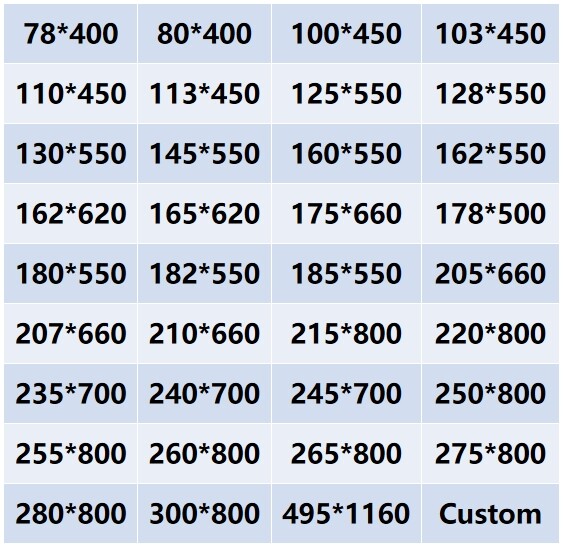

| Outer Diameter | From 400mm to 1160mm (15 3/4" to 45 2/3") |

| Common Size MOQ (Listed Below) | 100 Pcs |

| Custom Size MOQ | 2000 Pcs |

| Material | Wire/Poly/Mixed |

| Color | Default/Custom |

Product Description

FAQ

1.

Q:

What is the type of your company? Trading company or manufacturer?

+2.

Q:

What quality standards do your products meet?

+3.

Q:

Do you offer customization services?

+4.

Q:

What is the MOQ (minimum order quantity)?

+5.

Q:

Do you support international shipping?

+6.

Q:

Do you provide after-sales technical support?

+7.

Q:

Do you provide product samples?

+8.

Q:

May I visit your factory and office?

+

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT