Industrial brush rollers are specialized cylindrical brushes designed for heavy-duty applications in industrial settings. They are used in a wide range of industries and applications for tasks such as cleaning, surface preparation, material handling, and more. Below are some key points about industrial brush rollers:

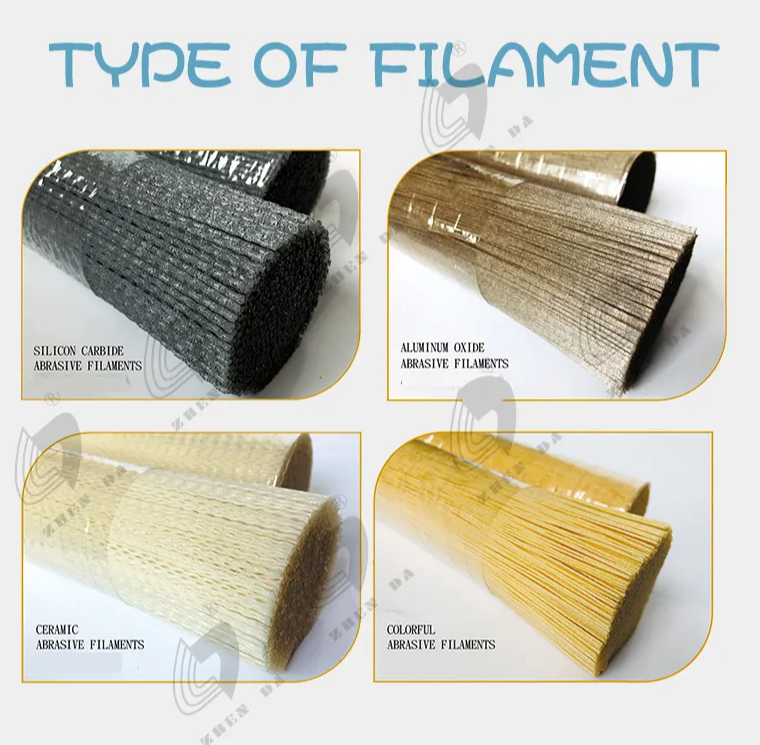

Construction: Industrial brush rollers are typically composed of a central core or shaft made of metal or high-strength plastic. The core serves as the rotational axis for the brush. Bristles or filaments are attached, inserted, or wound around the core. The bristles can be made of various materials, At Zhenda Brush, we offer natural fibers, synthetic fibers, wire, or abrasive materials for you to choose from, depending on your specific application requirements.

Size and Configuration: Industrial brush rollers come in various sizes and configurations to suit different applications. They can range from small-diameter rollers used in machinery to large-diameter rollers used in industrial cleaning equipment or conveyors. The density, length, and stiffness of the bristles can be customized to achieve the desired performance and functionality.

Applications: Industrial brush rollers have diverse applications across industries. They are commonly used for cleaning and surface preparation tasks, such as removing debris, dirt, or coatings from surfaces. They are also utilized in material handling applications, such as guiding, conveying, or aligning products on conveyor systems. Industrial brush rollers find use in industries such as manufacturing, food processing, printing, textiles, automotive, and more.

Customization: Industrial brush rollers can be highly customized to meet specific application requirements. The bristle material, density, length, and diameter of the roller can be tailored to suit the intended purpose. In some cases, the brush rollers may incorporate additional features such as special coatings, mounting options, or unique configurations to optimize performance. With its two decades of manufacturing expertise in industrial brush rollers, Zhenda Brush enjoys rich experience in the customization of industrial brush rollers.

Durability and Performance: Industrial brush rollers are designed to withstand rugged and demanding environments. They are engineered to be durable, long-lasting, and capable of withstanding heavy use and harsh conditions. The selection of bristle materials and core construction ensures optimal performance and reliability.

In summary, industrial brush rollers play a crucial role in many industrial processes, offering efficient and effective solutions for cleaning, surface treatment, and material handling. Their versatility, durability, and customization options make them valuable tools in various industries. Contact Zhenda Brush via the email below if you need an experienced industrial brush roller manufacturer for your business needs.

Business Email: marketing@zhendabrush.com

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT