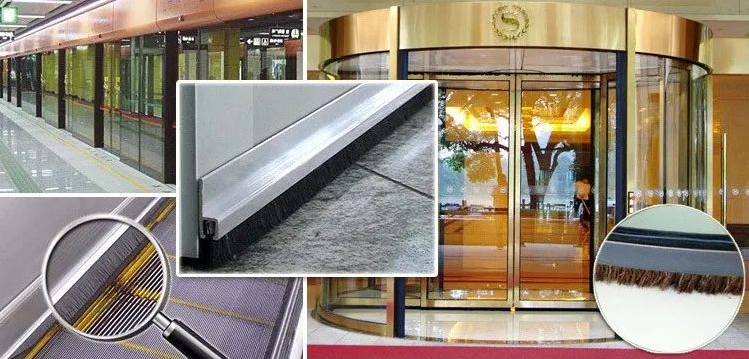

Strip brushes are indispensable tools in various industrial sectors, offering versatility, durability, and practicality. Their unique design and functionality make them highly effective in improving efficiency, maintaining cleanliness, and enhancing performance in industrial applications.

Conveyor Systems

Strip brushes play a crucial role in conveyor systems across multiple industries. They are used for various purposes, such as guiding, cleaning, sealing, and sorting. Strip brushes installed on conveyor belts help guide products along the desired path, ensuring smooth and efficient transportation. They also act as seals, preventing the infiltration of dust, debris, and contaminants into sensitive areas.

Manufacturing and Processing

In manufacturing and processing industries, strip brushes find extensive applications. They are used for cleaning, deburring, and surface treatment of materials and products. Strip brushes with abrasive bristles are employed to remove burrs, sharp edges, or unwanted materials from metal, plastic, or wood surfaces. They can also be used for polishing and finishing applications, ensuring a smooth and refined end product.

Dust and Debris Management

Industrial environments often generate significant amounts of dust, debris, and particles. Strip brushes are employed to manage and control these contaminants effectively. They are utilized in dust collection systems, where they act as seals, preventing dust from escaping into the surrounding environment. Strip brushes also find applications in material handling equipment, such as hoppers and chutes, to control the movement and dispersion of particles.

Surface Treatment and Finishing

Strip brushes are widely used for surface treatment and finishing applications in industries such as metalworking, woodworking, and automotive. They are employed in polishing, deburring, and cleaning processes to achieve desired surface finishes. Strip brushes with abrasive bristles can effectively remove imperfections, oxidation, or rust from metal surfaces, preparing them for further treatments or coatings.

Conclusion

Strip brushes are versatile and practical tools that offer numerous advantages in industrial applications. Whether in conveyor systems, manufacturing processes, dust management, or surface treatment, strip brushes play a vital role in enhancing efficiency, maintaining cleanliness, and improving performance. Their ability to guide, clean, seal, and control materials makes them indispensable in industrial settings, contributing to improved productivity, product quality, and workplace safety.

At Zhenda Brush, we pride ourselves on being a leading manufacturer of high-quality strip brushes, revolutionizing the way industries tackle their unique challenges. Contact us today to discuss your specific requirements and discover how our strip brushes can revolutionize your industrial applications.

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT