Strip brushes are flexible brushes made up of bristles that are attached to a metal or plastic strip. They are commonly used in various applications for sealing, cleaning, guiding, or conveying purposes. Below are some key points about strip brushes that will allow you to know them better.

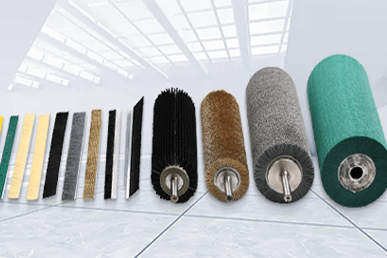

Construction: Strip brushes typically consist of a base strip, which can be made of materials such as aluminum, stainless steel, or plastic, and bristles that are attached to the base strip. The bristles can be made of various materials, such as nylon, polypropylene, or natural fibers, depending on the intended application. At Zhenda Brush, various bristle options are made available for you to choose from, including steel wire, copper wire, nylon, boar hair, horse hair, etc.

Versatility: Strip brushes are highly versatile and find applications in various industries. They can be used for sealing gaps and controlling airflow in doors, windows, conveyors, and industrial machinery. They are also used for cleaning, sweeping, dusting, and guiding objects on conveyor belts or production lines.

Customization: Strip brushes can be customized to meet specific requirements. The length, density, and material of the bristles can be tailored to suit the desired application. The base strip can also be cut to the required length or shape to fit different equipment or structures. As a experienced strip brush maker, Zhenda Brush can offer excellent customization services as per your requirements.

Sealing and Weatherstripping: Strip brushes are commonly used as weatherstripping or sealing solutions. They can be used to seal gaps, prevent drafts, control dust or debris, and reduce noise. They are often found in doors, windows, garage doors, and industrial enclosures.

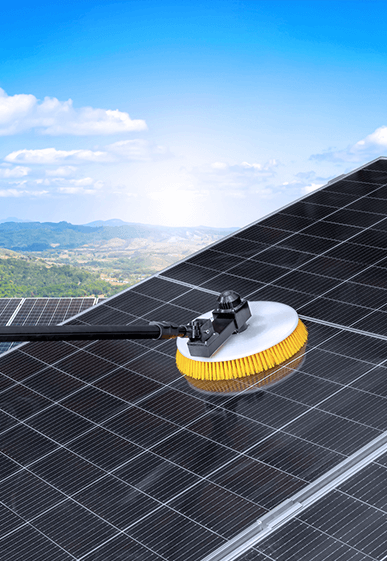

Cleaning and Deburring: Strip brushes with stiff bristles are used for cleaning surfaces, removing debris, or deburring sharp edges. They are effective in applications such as parts cleaning, conveyor belt cleaning, PCB cleaning, or removing excess material from machined parts.

Conveyor Systems: Strip brushes are widely used in conveyor systems to guide, support, or clean products as they move along the belt. They help prevent product jams, control the movement of items, and remove debris or excess material from the conveyor belt.

Industrial Machinery: Strip brushes are employed in various types of industrial machinery to provide sealing, protection, or guidance. They can be found in equipment such as food processing machinery, printing machines, packaging equipment, and woodworking machinery.

In brief, strip brushes offer a versatile and customizable solution for a wide range of applications. Their flexibility, durability, and ability to conform to irregular surfaces make them suitable for sealing, cleaning, guiding, and other industrial tasks. If you need quality strip brushes for your business, Zhenda Brush is here to help, please feel free to contact us via the following email.

Business Email: marketing@zhendabrush.com

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT